A Guide to Metal Stamping: Design

A Guide to Metal Stamping: Design

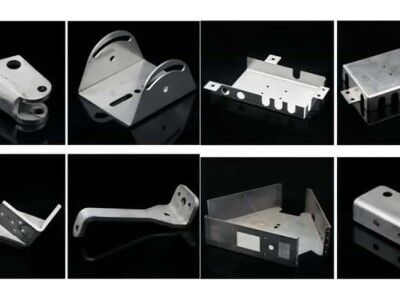

Metal stamping parts are the foundation of today’s society, whether in daily life, or in industrial activities, it plays an indispensable role. Whether it is home appliances, automobiles, electronic products, or mechanical equipment, metal stamping parts are applied in almost every field. Therefore, the design of metal stamping parts can be said to be the foundation of the foundation, and its importance cannot be ignored.

When designing metal stamping parts, several factors need to be considered to ensure that the final product can meet the functional requirements and production efficiency. This guide will detail some important factors to provide you with comprehensive information support.

Material Selection

When preparing a project, choosing the right metal material is the first step in the design of metal stamping parts. This process is not only related to the performance and quality of the final product, but also directly affects the production efficiency and cost control. Please refer to another guide: A Guide to Metal Stamping: Materials

Part Shape and Size

In the design of metal stamping parts, the shape and size of the parts are crucial factors. The shape complexity of the parts directly affects the feasibility and difficulty of the stamping process.

Overly complex shapes may require multiple stamping processes, increasing costs and production cycles, and may also lead to an increase in scrap rates. For example, shapes with sharp internal angles or deep and narrow grooves are prone to stress concentration and cracking during stamping.

In terms of size, too large size may exceed the processing capacity of stamping equipment, or require special large molds, increasing the investment cost. However, too small a size may require very high accuracy, which brings challenges to processing and measurement.

In addition, the size ratio of the parts also needs to be carefully considered. Too long a cantilever structure, too thin a wall or too large an aspect ratio can affect the strength and stability of the part, resulting in deformation or failure during stamping and subsequent use.

At the same time, we should also pay attention to the requirements of dimensional tolerance. Too tight tolerances can increase machining difficulty and cost, while too loose tolerances may not meet assembly or functional requirements.

Stamping Processability

In the design of metal stamping parts, stamping processability is a key consideration.

- Whether it can be stamped at a time is an important point. If it cannot be completed at once, multiple processes not only increase the cost and time, but also may affect the accuracy and quality consistency of the product.

- The quality of the blanking edge needs attention. A good blanking process ensures that the edges are neat and burr free, reducing subsequent trimming work.

- The feasibility of the drawing and bending process is also critical. When stretched, the flow characteristics and deformation uniformity of the material will affect the quality of the product. When bending, the bending radius and Angle should be selected appropriately to avoid cracks or excessive thinning.

- Rebound is a common problem. The springback characteristics of the material should be considered in the design, and the amount of springback should be controlled through reasonable process parameters and mold design to meet the dimensional accuracy requirements.

- Layout has a great impact on material utilization and production efficiency. Reasonable layout can reduce waste and cost.

- The structure and life of the die are also related to the stamping process. Complex processes may require more complex and expensive molds, while also affecting the service life of the mold and increasing maintenance costs.

Die Design

In the design of metal stamping parts, the structural rationality of the die directly affects the quality and production efficiency of the stamping parts. For example, the guide device of the die should be precise to ensure the accurate alignment of the upper and lower dies during the stamping process to avoid deviations resulting in unqualified parts.

The life of the die is also the focus of attention when designing. Through reasonable structural design, optimized heat treatment process and selection of high-quality die materials, the service life of the die can be extended and the production cost can be reduced.

Mold maintenance convenience can not be ignored. Molds that are easy to disassemble, install and maintain reduce equipment downtime and increase productivity.

More stamping die information, please refer to another guide: A Guide to Metal Stamping: Dies

Precision Requirement

In the design of metal stamping parts, clear dimensional accuracy requirements are essential. This includes the allowable deviation range of the basic dimensions such as the length, width and thickness of the stamping part. High precision requirements may lead to increased processing difficulty and cost; However, if the accuracy requirement is too low, it may not be able to meet the assembly or functional requirements of the product.

Accuracy can be divided into shape and position accuracy and surface accuracy.

- Form and position accuracy such as flatness, verticality, roundness, etc. These accuracy requirements are essential to ensure a good fit between the stamped parts and other components as well as the overall performance of the product.

- The surface roughness requirements will affect the appearance and frictional properties of the stamped parts. For example, certain surfaces that require a good sliding fit may require lower roughness.

In addition, the rebound and deformation during the stamping process will have an impact on the accuracy.

Production Cost

In the design process of metal stamping parts, production cost is one of the most important factors. This production cost is usually composed of three main categories: materials, processing and molds. See above for information on how to select materials and molds.

Processing costs include the operating costs of stamping equipment, manual operation costs and production efficiency.

Production Quantity

In the design of metal stamping parts, the batch size will directly affect the choice and design of the mold. For mass production, more durable, high-precision but higher-cost molds are usually used because the mold cost can be spread across a large number of products, thereby reducing the mold cost per unit product. And small batch production may choose a simpler, lower cost but relatively short life of the mold.

The production volume will also affect the development of the process plan. In mass production, it is more inclined to use a high degree of automation and high efficiency continuous stamping process to improve production speed and reduce labor costs. Smaller series production may employ more flexible and easily adjusted processes.

Strength and Stiffness

In the design of metal stamping parts, strength determines the ability of stamping parts to withstand loads without breaking or permanently deforming. The design needs to consider the maximum load in the work, and select materials with sufficient tensile strength, yield strength and fatigue strength. For example, in stamping parts subjected to dynamic loads, fatigue strength is particularly critical, otherwise it may fail prematurely under repeated action.

The stiffness is related to the ability of the stamping part to resist deformation when it is stressed. If the stiffness is insufficient, it may lead to dimensional deviation, affect the assembly accuracy, and even affect the stability and function of the entire structure. In the design, it is necessary to improve the flexural stiffness and torsional rigidity of stamping parts through reasonable shape design, such as increasing the reinforcement and changing the cross-section shape.

At the same time, the stamping process will also have an impact on strength and stiffness. Cold work hardening during stamping can improve the strength of the material, but excessive deformation can lead to internal defects and reduce strength and stiffness.

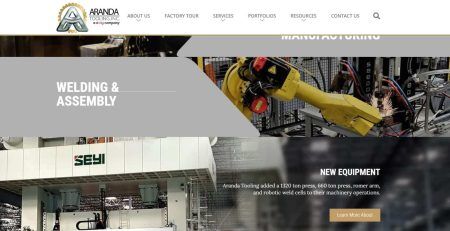

In addition, the connection mode will also affect the overall strength and stiffness. For example, with welded or riveted stamping parts, the design and process of the connection should ensure that the load can be effectively transferred and does not become a weak link in the structure.

Assembly Requirement

In the design of metal stamping parts, assembly requirements are a factor that needs to be paid attention to. The fitting tolerance between the stamping part and other parts is very important. Too loose coordination may lead to loosening, abnormal sound and even function failure; Too tight fitting will increase the difficulty of assembly and may even cause component damage.

Conclusion

In the actual design of metal stamping parts, there are many factors involved, and this guide only lists the general factors.

Attention should also be paid to the development trends of new technologies, new materials and new processes that may appear in the future. These changes may affect the existing design scheme, so regularly reviewing and updating the project will make metal stamping parts always at the forefront of technology to better meet market demand.

It is hoped that through this guide, you can provide comprehensive information support for your metal project, so that you can make more effective decisions and achieve the desired goals.