Top 10 Most Popular Metal Stamping Manufacturers in US

Top 10 Most Popular Metal Stamping Manufacturers in US

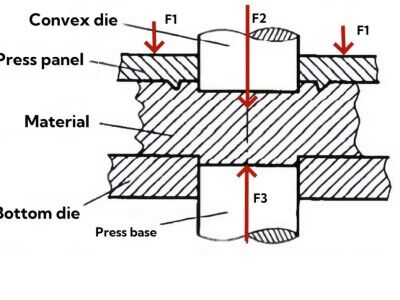

Metal stamping is an effective metal manufacturing solution that is widely used in various industries, including automotive, electronics, aerospace and home appliances. Through this process, parts with complex shapes and high precision requirements can be efficiently produced, thus meeting the needs of modern manufacturing for product diversity and flexibility.

Choosing the right metal stamping manufacturer is an important thing, which is not only related to product quality, but also directly affects the overall progress and cost control of the project. A good manufacturer usually has advanced equipment and technology, and can provide one-stop service from design, raw material procurement to finished product delivery.

In addition, they have accumulated extensive experience in the industry and are able to customize production according to the specific needs of customers to ensure that the final product meets the expected standards.

According to relevant data, the global metal stamping market has been growing at an alarming rate. Some leading metal stamping manufacturers are listed below.

Wiegel Tool Works, Inc

Wiegel provides leading OEM and tier manufacturers across the globe with progressive die heavy and high-precision metal stamping services. We support custom, high-volume metal stamping production requests for precision, electrical connectors, contacts, and various other electrical and non-electrical component parts. We offer in-house support of rapid prototyping, tool design and tool production, waterjet, and assembly services. We’re known for investing in our industry’s top stamping production technology and the deployment of strong quality controls through our signature in-line/off-line camera vision systems and sensor technology. Our continual equipment investments are what enable us to meet new and evolving industry developments and greater production efficiencies, reach competitive pricing and achieve better product results.

Acro Metal Stamping

Acro Metal Stamping

Since 1942, Acro Metal Stamping, located in Milwaukee, Wisconsin has been producing precision production stampings in all shapes, sizes and materials. We provide competitive pricing utilizing the latest technology in the metal stamping industry to provide top quality products with our state-of-the-art equipment.

Our workforce is highly trained and our equipment is updated to meet any requirement, this includes a fully programmable Servo presses featuring accuracy within microns. From sheet metal stamping to carbon steel, brass, copper, and plastics, we work with any material you need, at any thickness..

ACRO Metal Stamping has a complete in-house toolroom that can design, engineer and manufacture all types of compound, progressive, draw and prototype tooling to meet your requirements. We also have wire EM capabilities. We will store, repair and maintain your dies at no cost to you.

With our state of the art metal stamping equipment, unparalleled expertise, competitive pricing, and JIT delivery of your metal stampings, we are the best precision metal stamping company for your production needs.

ESI Engineering Specialties Inc

At ESI, we understand the worlds where our customers work. For more than three decades, we’ve built our company on delivering a new level of engineering solutions and manufacturing services, including the latest automated systems. In fact, a major part of our experience comes from serving automotive clients with safety-critical parts—one of the most quality, time and efficiency-driven industries in the world.

We’ve designed an automated assembly machine that simultaneously inspects every part for 10 criteria, using advanced vision technology. Built for a unique seat-belt application, this system is just one of the technologies we’ve created to meet precise specifications. Fully automated, it eliminates labor costs. Inspecting every single part, backed by Six Sigma Black Belt Trained QA personnel, ESI takes quality assurance to new heights.

Pacific Metal Stampings, Inc

Pacific Metal Stampings, Inc

Since 1968 Pacific Metal Stampings has specialized in producing metal components for hundreds of aerospace, automotive, electronic, military, green technologies, and industrial customers. We operate 27 punch presses, ranging in size from 22 to 165 tons, which produce simple and complex shapes from dies produced in our own tool and die department.

Located north of Los Angeles, in Valencia California, we are large enough to offer you full-service metal stamping capabilities, yet small enough to work with you day to day on a personal basis. Let us work with you to find the most cost effective way to produce your parts. We’ll gladly provide you with a list of satisfied Pacific Metal Stampings customers. Requests for quotes are typically returned within 24 hours.

While there has been a trend to move manufacturing operations off shore in an effort to stay competitive in today’s world economy, Pacific Metal Stampings took a different approach. With the assistance of the Employee Training Institute at the College of the Canyons in Valencia, CA, Pacific Metal Stampings enrolled over half of our employees in Lean Manufacturing classes, consisting of 140 hours of training over a 12 month period. As a result of the training, the thru-put, on-time delivery and work in process dramatically improved, while allowing for an increase in capacity.

TenRal Metal Products Ltd

TenRal Metal Products Ltd

TenRal is a seasoned metal stamping company with over 15 years of experience in China. Since 2005, we have been supplying precision metal stamping parts to clients across various industries such as automotive, lighting, construction, medical, energy and more. As the premier manufacturer of metal stamping, we boast a professional team and state-of-the-art facilities to deliver the most dependable metal stamping components to our customers.

In 2023, we added a new workshop and established a headquarters. The 53,000 square foot headquarters is equipped with new sheet metal fabrication equipment, such as cutting machines, CNC bending machines, automatic powder coating lines, and more, which enables us to provide the most comprehensive sheet metal fabrication services.

In 2024, we successfully purchased a stake in a new CNC machining company, which will become a sub-workshop of TenRal. The workshop is equipped with more than 20 advanced CNC machining equipment from Japan and South Korea. These high-precision equipment can meet a variety of complex processing needs, mainly providing metal turning and metal milling services.

Talan Products, Inc

Founded in 1986, Talan Products began with one metal stamping die and one customer. Since then, it has evolved from humble beginnings to become a full-service metal stamping company and manufacturer of tooling and engineered parts diversified operation serving OEMs across a variety of industries.

Today, Talan is one of the most acclaimed stampers in the U.S., producing a variety of products for more than 150 customers in the fastener, building products, appliance, hardware, defense and transportation markets. The company has proudly held ISO certification since 1999 and currently holds ISO 9001:2008 certification.

Talan has recently expanded into the solar and LED markets. The solar business is a natural outgrowth of the company’s understanding of commercial roofing systems because of its knowledge of how the solar collectors need to interface with the building racking/mounting system. In addition, Talan has worked with an international lighting company, and LED lighting ventures are creating new opportunities for growth.

Keats Manufacturing Co

Keats Manufacturing Co

Keats Manufacturing Co. produces the most intricate custom small metal stampings, wire forms, and assemblies in the world. The Company was founded in 1958 and now has 3 locations that house more than 175 metal stamping and wire-forming machines. Keats operates four slide/multi-slide and stamping press technologies 5 days a week, 24 hours a day. This means that Keats can handle virtually any size order from prototypes to over 500 million pieces. Industries we serve include automotive, appliance, medical, aerospace, communications, electronics, military, construction, furniture, and more.

Keats designs and develops all of its own dies and tools, ensuring that the most exacting tolerances are maintained from the first to the last production run. All of the Keats facilities are ISO & IATF certified. Strict adherence to the quality control system results in customer satisfaction and, more importantly, customer confidence.

MW Components

MW Components is focused on accelerating the entire process of delivering custom, stock, and standard parts to virtually any volume and against demanding deadlines. We work to highly complex tolerances. We help simplify the management of any number of different components. And we take a no-compromise approach to quality. With MW Components you can be sure you’ll get the right part to the right specification when and where you need it.

Wedge Products, Inc

Since 1933, companies worldwide have relied on Wedge Products to deliver quality metal stamping products, on time and at a competitive price. We are an aerospace certified stamper offering a full range of services. At our modern 110,000 square foot facility, Wedge produces metal stampings and plastic stamping from a wide range of materials and thicknesses. Our experience has served to establish us as one of the pre-eminent manufacturers of deep draw stampings. Customer satisfaction is our primary goal. The operating philosophy of Wedge Products is to exceed our customers needs and expectations through our “hands-on” management team.

Clow Stamping Company

Clow Stamping Company

Clow Stamping Company in Minnesota is a top provider and industry leader in full-service metal stamping and fabrication of metal components. Our profound focus on quality and customer care is one of the largest reasons we have experienced growth over time.

We stand for quality on-time delivery and take pride in our craftsmanship. Our ISO certification is just one example of our dedication to quality. Through cutting edge technology, years of experience, and hard work we do it right, the first time.

When we started operations in 1970, we did so with two goals in mind: providing you with the highest quality parts and service as if we were a partner in your business.

We have the best available technology, tools, equipment, and most importantly, the best people in the metal fabrication industry. Our customer service cannot be beaten. As a metal stamping company, we strive for perfection. We provide constant communication through production, keeping you informed every step of the way.

Final Thoughts

These metal manufacturers are the most popular in the United States in 2024 and have established a good reputation in the industry with their superior technology, quality products and good customer service. It is hoped that this guide will serve as a reference in your decision making process and help you find the metal manufacturer that best suits your project requirements for efficient collaboration and smooth progress. At the same time, we also look forward to bringing more value and success to your project through cooperation with these outstanding enterprises.