Top 8 Metal Fabrication Companies in the US

Top 8 Metal Fabrication Companies in the US

As sheet metal parts play an increasingly important role in today’s society, precision sheet metal fabrication is particularly critical. Sheet metal parts are widely used in various industries, including automotive, aerospace, electronic equipment and construction.

In the United States, there are many excellent sheet metal fabricators, they rely on a wealth of experience and expertise to provide customers with high quality, efficient service. With this guide, we’ll introduce these top companies to help you make an informed choice.

Factors for Choosing a Sheet Metal Fabrication Company:

- Technical competence and professional experience: Understand their experience in the industry, especially in working on projects similar to your needs.

- Equipment and facilities: Check to see if it has the latest CNC machine tools, laser cutting equipment, bending machines, etc.

- Quality control system: Understand their quality inspection methods, inspection frequency, and treatment measures for nonconforming products

- Production capacity and flexibility: Assess the manufacturer’s production scale and capacity to fulfill your order on time, especially if the order volume is large or there is an urgent need. At the same time, it is also necessary to consider its flexibility in production arrangements and whether it can adapt to design changes and other needs.

- Cost and price: Compare quotes from different manufacturers, but not only focus on price, but also consider cost-effective, including product quality, delivery time and other comprehensive factors.

- Lead time: Understand the manufacturer’s delivery commitments and past delivery records.

- Customer Service and communication: Good communication channels and active customer service reduce misunderstandings and problems.

- Material supply: Understand the source and quality of the manufacturer’s materials.

- Innovation ability: Can provide you with more optimized design and manufacturing solutions, reduce costs or improve product performance.

- Reputation and reference cases: Look at the manufacturer’s market reputation and refer to similar projects they have completed for other customers.

Here are the top 8 sheet metal manufacturers in the United States:

TITAN Metal Fabricators

TITAN Metal Fabricators

- Headquarters: Camarillo, CA

- Founded: 1998

- Field: Pressure Vessel Design and Manufacturing, Heat Exchanger Design and Fabrication

Experts in the design & manufacture of process equipment with corrosion-resistant alloys, TITAN is trusted around the globe within the chemical, petrochemical, oil & gas, liquified natural gas (LNG) and pharmaceutical industries. TITAN’s reputation stems from its extensive experience, proven capabilities, and high degree of personalized customer service all performed by the company’s team of engineers, manufacturing professionals, quality control engineers, and skilled support.

Southern Metal Fabricators, Inc.

- Headquarters: Albertville, AL

- Founded: 1991

- Field: Custom Metal Fabrication, Industrial Stairs, Ductwork, Hydrocyclones, Hoppers, Bins, Tanks, Platforms,Industrial Ladders and Material Handling Equipment

Southern Metal Fabricators is a custom manufacturer offering a wide variety of components for a wide variety of industries. Whether your need is for a single item or a continuous production item, Southern Metal Fabricators is eager to work with you!

Established in 1991 as a two-man shop serving maintenance and light fabrication needs of local industry, Southern Metal Fabricators has become an aggressively growing custom metal fabricator. Vision driven, Southern Metal Fabricators continually seeks qualified employees, invests in increased capabilities, and actively pursues broader markets. Our goal is to meet or exceed your requirements with respect to quality, budget, and delivery.

Chicago Metal Fabricators

- Headquarters: Chicago, Illinois

- Founded: 1908

- Field: Heavy Plate Fabrication, Large Laser cutting, Robotic Press Brake Forming, Bending

Founded in 1908 on the city’s southwest side, Chicago Metal Fabricators is a fully integrated fabricator with more than 200,000 sq ft in Chicago and 60,000 sq ft in Elk Grove Village, Illinois. With over a century of experience to our credit, CMF has fabrications in work around the globe. Starting as a metal cabinet and ductwork fabricator in the early 20th century, CMF is now a fully integrated fabricator specializing in heavy components and large assemblies accommodating up to 30 tons in the Chicago facility with a highly automated light facility in Elk Grove Village. Chicago Metal Fabricators broad and high quality fabrication capabilities make us a leading fabricator nationwide.

Prototek Digital Manufacturing

- Headquarters: Contoocook, New Hampshire

- Founded: 1987

- Field: CNC Machining, Precision Sheet Metal Fabrication, Plating, Rapid Prototyping, Water Jet Cutting, Laser Sintering

Prototek is a leading on-demand digital manufacturer specializing in additive manufacturing, CNC machining, sheet metal fabrication, silicone/urethane casting, and more. We have over 100 materials and more than 40 surface finishes to get your ideas made.

Today, we have manufacturing facilities in Wisconsin, Silicon Valley, Pennsylvania, Colorado, and New Hampshire under the Prototek umbrella.

TenRal Metal Products Ltd

- Headquarters: Foshan, Guang Dong

- Founded: 2005

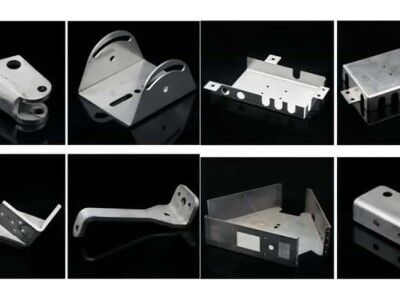

- Field: Precision Sheet Metal Fabrication, Cutting, Bending, Welding, Finishing, CNC Machining, Metal Stamping, Tool design and manufacturing, Rapid prototyping

TenRal is a specialized metal manufacturing company located in China. Since its inception, we have focused on the production of various types of metal components, including but not limited to aluminum alloy, steel and stainless steel products. These products are widely used in many fields such as automotive, aerospace, electronic equipment and construction.

We are committed to providing the most reliable metal manufacturing services to our customers in various industries, ensuring that every product meets strict quality standards. In order to meet the changing market demand, we have introduced advanced production equipment and adopted modern management processes to improve production efficiency and product accuracy. In addition, we have an experienced and skilled team, which can customize the design and production according to the specific requirements of customers.

Send Cut Send LLC

- Headquarters: Reno, Nevada

- Founded: 2018

- Field: Laser cutting, waterjet cutting, manufacturing on demand, prototypes

In 2018, SendCutSend was born. With dogged determination, they automated processes, created an instant quoting system, and slashed turnaround times and cost. In the end, they created the fastest way to cut and ship precision laser cut metals, from one-off prototypes to full production runs – at 10x less the cost of traditional shops.

Today, SendCutSend offers laser cutting, waterjet cutting, and CNC routing, and 10+ secondary services. They cut more than 8 million parts a year and recently were recognized as a top 5000 Inc. company.

Evansville Sheet Metal Works, Inc.

- Headquarters: Evansville, Indiana

- Founded: 1946

- Field: Custom Aluminum and Stainless Steel Fabrication, AWS Certified Welding and Custom cut metal

Evansville Sheet Metal Works, Inc. (ESMW) has been in the custom fabrication business since 1946. We make, modify, and improve manufacturing equipment for many industries, including automotive, pharmaceutical, nutritional, and plastics.

In 2010 we launched Cut2SizeMetals.com, an easy-to-use website that allows customers to order precision-cut pieces of metal, and have them shipped the same day to their door.

Approved Sheet Metal

- Headquarters: Hudson, New Hampshire

- Founded: 2020

- Field: Sheet metal fabrication, rapid sheet metal, prototype sheet metal, sheet metal assemblies, weldments

Founded by accomplished sheet metal fabrication industry experts. Approved Sheet Metal (ASM) is an American job shop manufacturer of custom precision prototype and low volume production sheet metal fabricated parts.

When it comes to sheet metal fab, precision is key. At ASM, we offer custom metal fabrication services to meet the exact specifications of your 3D Model and/or print. Our highly experienced team can work with a variety of materials, including steel, aluminum, and stainless steel, to create high-quality sheet metal parts for a range of industries and applications. Our extensive in-house capabilities paired with our team’s extreme attention to detail on every project ensure accuracy and consistency across the thousands of unique parts we see monthly. With fast RFQ turnaround and lead times that can’t be beaten ASM is the go-to choice for all of your sheet metal fabrication needs.

Take your product development process to the next level by leveraging our 30+ years of prototype and low-volume production sheet metal fabrication experience. ASM will fabricate a single prototype sheet metal part to low volume production of sheet metal quantities in the thousands. Our shop utilizes state-of-the-art software, seasoned employees, and top-of-the-line equipment to get parts out the door quickly and done right the first time.

Conclusion

This guide is intended to provide a brief introduction to some of the outstanding sheet metal fabrication companies for your reference. However, there are actually many other excellent sheet metal fabricators with excellent technical capabilities and extensive industry experience.

Different companies may have their own areas of expertise, some focusing on high-precision components, while others may be more adept at mass production. Therefore, before making a decision, it is advisable to conduct detailed research on potential suppliers and communicate with them in depth to ensure that your specific needs are met.